Produts e ProcesseS

CIE Stratis runs 4 painting lines that can accommodate, within their differentiators, nearly all aesthetical applications requested by the automotive sector from monolayer satin or glossy coats up to 4 layers, wet on wet straight application assuring both quality and competitiveness

Our lines range between flat bed and vertical liquid aerographic application, all of them with vertical axis rotation, and from 1 booth to 4 within the conveyor’s loop

Flaming treatment could also be applied to the raw surfaces as well as oven demanding primers applications, and UV curing, on the go. One of our painting lines is pure semi automatic, with manual paint application, one is hybrid being fully automatic for monolayer and semi automatic for multilayer applications, and two are fully automatic while all of them are equipped with state of the art mixers for paint preparation and blending.

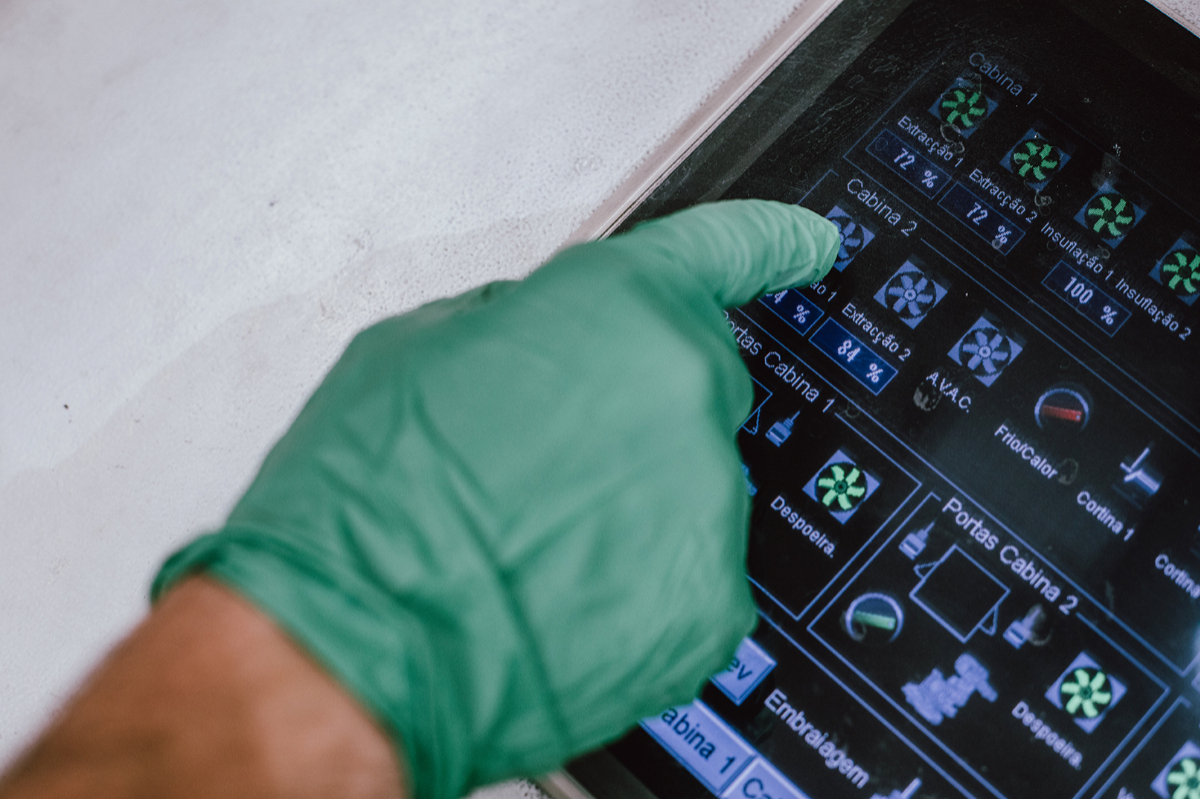

Our painting processes can brace all paints from water born to solvent based painting systems and clear coat booths on automatic lines, do have air conditioning systems to control temperature and moisture levels and the same happens around cooking, technical areas and paint storage.

Painting is our core activity but Hot Stamping, Tampo Printing and Laser Marking and Etching crown the portfolio of decorative processes offered by our company that are complemented with welding and assembling operations to offer a final part ready to be shipped and assembled on a module, or directly trim the vehicle.

We produce parts all across exterior and interior of vehicles that rely both all over dashboard, door panel and central console, on the interior, as well as integrating bumpers, spoilers, roof systems and others on the exterior.

Our parts rely both in hidden areas providing crucial features, and at sight, all over dashboard, door panel, central console and seats, on the interior, as well as integrating bumpers, spoilers, roof systems and others on the exterior.

Internal processes and conditions, are managed using an integrated erp mrp system across the plant that give us real time awareness and industrial data driven decision making, while also being logged for backtracking traceability.